Flame retardancy and thermal behavior of polycarbonate

ABSTRACT:

A new kind of flame retardant (ZS) with layered α-zirconium phosphate disks (α-ZrP) as the core and inorganic flame retardant (gel-silica, GS) to shield solid acid sites on the surface of α-ZrP as the shell, was synthesized via a facile method.

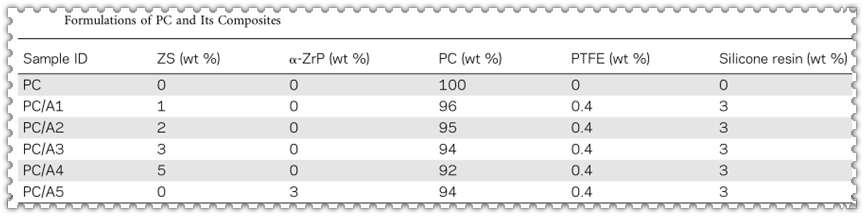

The incorporation effects of ZS with silicone resin on the thermal properties and flame retardance of PC composites were investigated.

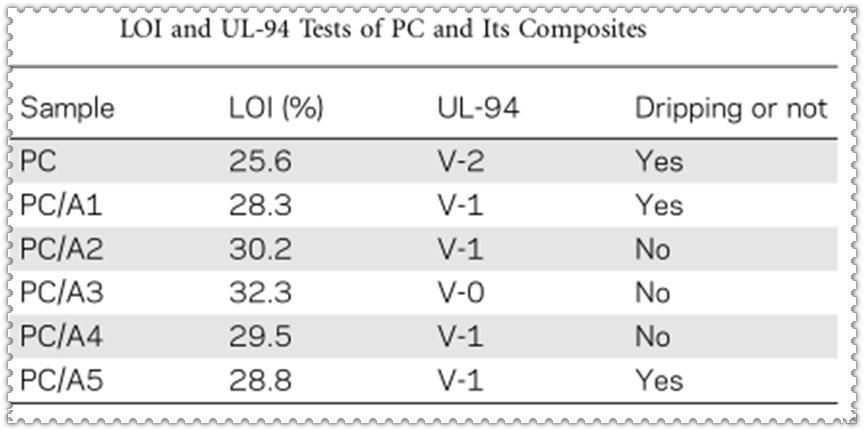

The presence of ZS could improve the thermal stability of PC matrix. With the addition of ZS contents increased to 3 wt %, the limiting oxygen index (LOI) of the composite was 32.3% and the vertical burning (UL-94) test reached a V-0 rating.

However, with more contents of ZS, the LOI value decreased, and without the GS layer, the LOI value was decreased significantly as well.

The synergism between the α-ZrP core and gel-silica shell, also with the silicone resin were found. Based on these results, the flame-retardant mechanism was proposed.

EXPERIMENTAL

RESULTS AND DISCUSSION

Flame-Retardant Mechanism of PC Composites

The detailed mechanism on the synergistically enhanced flame retardance by the combination of GS layer with α-ZrP core,also with the synergism between α-ZrP core and SR is proposed as following.

Herein, with the presence of ZS and SR, the main mechanism is believed to take place in the condensed phase.

With the temperature rising, the GS layer could do favor to protect the PC matrix from early degradation as the existence of Lewis acid sites on the plates of α-ZrP are covered, especially in the composite preparation processing.

Meantime, a glassy SiO 2 layer is formed and migrated to the outer surface, making the competition reaction with the chain scission fragments move to the crosslink direction and catalyzing the adjacent polymer crosslinking and charring to some extent.

Concurrently, SiAOAP bonds are formed which is ascribed to the synergism between α-ZrP core and SR.

And this synergistic effect could make more organic polysiloxane fragments existing with the α-ZrP residue which could drag the organic Si containing degraded product with intrinsic flame and heat-resistance from migration to the outer surface, remain playing the key role of consolidating the char layer by suppressing the polymer from melt dripping.

Moreover, the influence of SR here could enhance the amount of final char residue, and act as the char forming agent to support the char layer to some extent.

Pyro-phosphate, α-ZrP residue, which could not only dehydrate but also strengthen the char, acts as framework of the char layer and constructs the char layer with better quality.

Besides, a gradient distribution is indeed present in the char layer, which could strengthen the char layer to resist the heat and gas flow,make it more stable to work as condensed barrier.

In this case, the combination of chemical advantages and physical advantages exhibits a comprehensive function to prevent contact between combustible matrix and oxygen.

CONCLUSIONS

A core-shell structured α-ZrP@gel-silica flame retardant was successfully synthesized via a facile strategy.

Compared with the raw α-ZrP, the flame retardant ZS exhibited advantages of α-ZrP core and GS layer.

This combination not only enhanced the thermal stability of PC composites, especially the initial decomposition temperature (T5% ), but also could enhance the yield of char residue, due to the synergism between the core and shell.

The incorporation of ZS and SR lead to the formation of Si-O-P structure, which would result in the significant improvement in flame retardance of PC mixtures.

When the addition of ZS was increased to 3 wt %, the composites could reach a LOI value of 32.3% and a V-0 rating.

By comparison of α-ZrP with or without shell, it could be found that the coating layer could not only shield the solid acid sites on the surface of α-ZrP core, so that could protect the PC composites from degradation in the polymer melt mixing process, but also could combine with the pyrolysis molecular cracks to form an oligomer network, resulting in the improvement of flame retardance. Interestingly, not only the process of chemical reactions but also the gradient distribution of physical advantages could enhance the flame retardance by a comprehensive flame-retardant mechanism, including the gas phase mechanism and more importantly, the condensed phase mechanism.

(ARTICLE IN WILEYONLINELIBRARY.COM/APP)

Follow WeChat