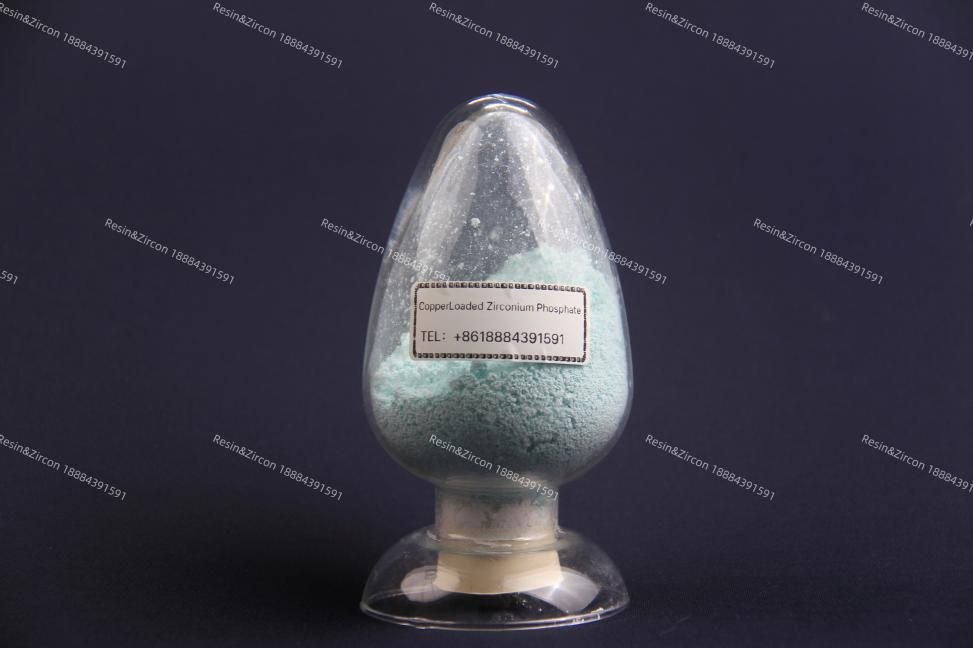

Copper Loaded with Zirconium Phosphate

Copper-loaded Zirconium Phosphate (ZRC), also known as copper-loaded zirconium phosphate, is a green powder that serves as an antibacterial agent based on layered zirconium phosphate. It boasts high safety and excellent heat resistance, along with good chemical stability. This additive can be incorporated into various resins to provide antibacterial effects, demonstrating broad-spectrum efficacy against multiple bacterial species. The inorganic antibacterial powder features smaller particle sizes and superior heat resistance, making it particularly suitable for melt spinning processes in synthetic fibers (e.g., polyester, polypropylene, nylon) and ceramic products requiring higher thermal stability.

Zirconium phosphate loaded in the heart can currently produce 7%-10% copper content, and the particle size, PH value and copper content of zirconium phosphate itself can be flexibly adjusted according to the requirements of different products.

Scope of Application:

Can be added to a variety of synthetic resins (such as PP, PE, PVC, PS, PET, ABS, etc.), various adhesives, various ceramics and artificial stone and synthetic fibers.

Plastic products: refrigerator shell, inner tank. Telephone shell, computer keyboard, washing machine plastic parts, power plastic switch and so on

Daily enamel: ceramics, glass products. Such as bowls, plates, sanitary ware, drinking utensils, etc

Textiles: Fibers, bedding, medical supplies, underwear, etc.

Shoe material: middle lining, surface lining, insole, etc.

Packaging materials: plastic packaging bags, food packaging boxes, bag film, etc.

Medical materials: disposable syringes, infusion sets, isolation suits, etc.

1. Product Features

1.1 Copper-loaded zirconium phosphate is a broad-spectrum antibacterial agent, which has a lasting effect on killing and inhibiting bacteria, is harmless to human body, and has no irritation to skin. It is a safe and non-toxic product.

1.2 Can withstand 1300℃ high temperature, and is not easy to discolor.

1.3 The powder has small particle size, uniform particle size distribution and large specific surface area. After surface treatment, it can be compatible with a variety of resins without affecting the processing properties and other properties of the material.

1.4 Can be permanently combined with polymer materials, and has good chemical stability. It can withstand repeated washing with surfactants in a wide range of PH, and its antibacterial force does not decline.

1.5 Powder surface treatment can be carried out according to user requirements to achieve the best dispersion in the medium matrix.

1.6 The resin compatibility is better than that of zeolite and silica gel antibacterial agents.

1.7 Ultra-low toxicity, LD value is much larger than other inorganic antibacterial agents.

1.8 High transparency, applied in transparent plastic products without affecting its transparency.

2. Recommended Additions

Add to synthetic resin or fiber, powder or plastic (fiber) masterbatch can be selected according to the specific production situation. Add to coatings, adhesives, artificial stone and so on, only the powder can be directly added. Add amount: according to the specific situation such as sterilization rate requirements, the add amount is 0.5%-1.0%.