Sunshine Factory, Co., Ltd. > Applications > ZrP for PolymerZrP for Polymer

Innovative Composites Based on Organic Modified Zirconium Phosphate and PEOT/PBT Copolymer

Abstract

Polymers are key building blocks in the development of smart materials for biomedical applications, and many polymers offer unique properties for specific applications.

A wide range of materials is available through the use of polymer compounds.

These compounds can incorporate performance-enhancing fillers, which provide properties not reachable with ordinary neat polymers (e.g., bending stiffness, tensile strength, elongation, torque, biological activity such as antimicrobial properties, cell differentiation). In this work, the preparation of functional biocomposites containing organic modified zirconium phosphate (ZrP) as drug carrier is presented.

The composites were prepared by melt compounding, which offers significant promise since it allows an easy customization of the plastic compounds that well suit biomedical applications (devices, long-term implantable polymers, bioresorbable polymers).

The obtained polymer composites based on ZrP intercalated with gentamicin (GMT) and poly(ethylene oxide terephthalate)/poly(butylene terephthalate(PEOT/PBT) were characterized.

Introduction

Organic–inorganic hybrid materials based on lamellar solids are innovative compounds that allow the development of multifunctional fillers for polymer composites .

Alpha-Zirconium phosphate is a lamellar solid with interesting properties to be used for the development of such hybrid materials .

ZrP structure indeed is composed by stacking layers made of planes of Zr atoms bonded, on both sides, to monohydrogen phosphate groups. each phosphate group is bonded to three Zr atoms of the plane, while each zirconium is octahedrally coordinated by six oxygens of six different monohydrogen phosphate groups. the water molecules are located in the zeolitic cavities of the interlayer region .

Zirconium phosphate can be easily functionalized through intercalation reactions, and has been widely studied in academic literature with the aim of vehiculate bioactive organic molecules .

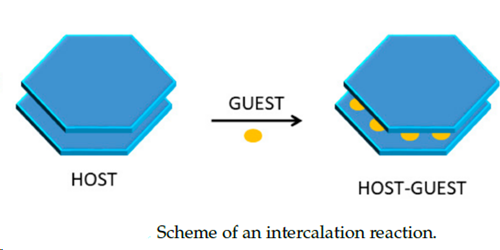

The term ‘intercalation’ refers to a reversible process where a guest molecule or ion is inserted into the interlayer region of a host lamellar matrix .

In Pic, it is reported a scheme of the intercalation process, where the host is Zirconium Phosphate and the guest is the organic active. Moreover, the

electrostatic interactions of the guest molecules and the lamellae of the ZrP also increase its chemical and thermal stability.

The term ‘intercalation’ refers to a reversible process where a guest molecule or ion is inserted into the interlayer region of a host lamellar matrix .

In Pic, it is reported a scheme of the intercalation process, where the host is Zirconium Phosphate and the guest is the organic active. Moreover, the

electrostatic interactions of the guest molecules and the lamellae of the ZrP also increase its chemical and thermal stability.

In this work, the preparation and characterization of an organic-inorganic hybrid based on gentamicin antibiotic and synthetic zirconium phosphate (ZrP-GTM) are presented .

This hybrid was employed as filler for the preparation of the polymer composites produced with the melt compounding technology assisted by twin screw extruder.

This hybrid was employed as filler for the preparation of the polymer composites produced with the melt compounding technology assisted by twin screw extruder.

For this purpose, the poly(ethylene oxide terephthalate)/poly(butylene terephthalate) copolymer(PEOT/PBT) was chosen.

The thermoplastic elastomeric properties of these multi-block copolymers are obtained by phase separation of the hydrophilic and hydrophobic segments in the polymers;this makes this block of copolymers highly interesting for the 3D printing manufacturing.

The thermoplastic elastomeric properties of these multi-block copolymers are obtained by phase separation of the hydrophilic and hydrophobic segments in the polymers;this makes this block of copolymers highly interesting for the 3D printing manufacturing.

The polymer has a relatively low melting viscosity, while after cooling it exhibits very good mechanical properties.

The possibility to balance hydrophobicity/hydrophilicity of the surface also makes these polymers very interesting for tissue engineering.

Composite Characterization

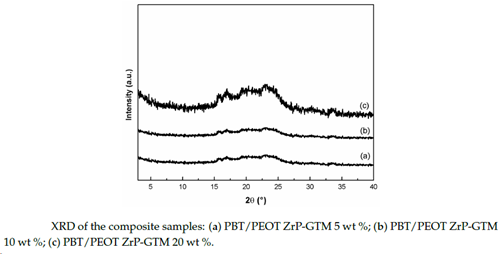

The polymer composites were prepared, by melt extruding PBT/PEOT with increasing amounts of the synthesized fillers. In detail, composites with 5,10 and 20 wt % of ZrP-GTM were realized.

No signals of the lamellar filler were detected suggesting a good compatibility between the organo-modified filler and the polymer. the organic modification of the filler with gentamicin seems to produce a good dispersion and confers to the masterbatches antibiotic activity.

Antimicrobial Activity

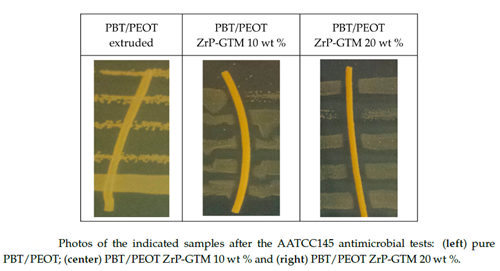

The biocidal activity of the composites was evaluated. The analysis was carried out by monitoring the growth of Staphylococcus epidermidis (Gram+), identified as one of the bacteria responsible for septic scaffolding failure in polymer implants.

Pure PBT/PEOT and composites with 10 and 20 wt % of ZrP-GTM were evaluated using theAATCC145 Test Method, which is a qualitative test for detection of the antimicrobial activity.

The method was applied to a precise and weighed quantity of polymer wires, as obtained at the exit of die extruder. In Figure , the experimental results of the analysis are reported.

Staphylococcus epidermidis colonies correspond to the yellow lines perpendicular to the polymer wires.

From the photos, it is evident that, with the neat polymer, the growth of bacteria is diffused; therefore, no antimicrobial effect can be detected for the pure polymer (as expected).

In both composites, with 10 and 20 wt % of ZrP-GTM, respectively, the growth of the bacteria is inhibited; in fact, near the wire areas, no colonies are detected confirming the biocidal activity of the composites. Since PEOT/PBT is a bioresorbable polymer , it is expected that the polymer will slowly dissolve/degrade in the biological medium freeing up the ZrP-GTM included in the composite material.

From the photos, it is evident that, with the neat polymer, the growth of bacteria is diffused; therefore, no antimicrobial effect can be detected for the pure polymer (as expected).

In both composites, with 10 and 20 wt % of ZrP-GTM, respectively, the growth of the bacteria is inhibited; in fact, near the wire areas, no colonies are detected confirming the biocidal activity of the composites. Since PEOT/PBT is a bioresorbable polymer , it is expected that the polymer will slowly dissolve/degrade in the biological medium freeing up the ZrP-GTM included in the composite material.

The biocidal activity can be attributed to the ability of ZrP-GTM to slowly release the gentamicin , which possesses a well-known antibiotic activity.

Remark:Article in J. Compos. Sci. 2018, 2, 31

Follow WeChat