Sunshine Factory, Co., Ltd. > Applications > ZrP for CoatingZrP for Coating

Scratch epoxy coating containing zirconium phosphate

Abstract

A facile but efficient spray-coating method was developed to manufacture thin, flexible, and transparent epoxy films.

The Results showed that scratch resistance is considerably improved after introducing ZrP nanofillers to the epoxy coating. This was reflected by the delay in microcracking and plowing damages and the decrease of scratch coefficient of friction.

That was attributed to the significant role of exfoliated andaligned ZrP nanofillers in enhancing the mechanical properties of the epoxy matrix.

Preparation of model coating systems

Three coating systems, namely neat epoxy, epoxy-M1000, and epoxy/ZrP-M1000.

Discussion

Engineering tensile stress-strain curves of the studied coating systems.

Tensile Properties of neat epoxy, epoxy-M1000, and epoxy/ZrP-M1000 thin films

Epoxy/ZrP-M1000 coating has the highest scratch performance

SCOF curves of the different model coating systems across the scratch path (SCOF is a good indicator for the different transitions across scratch-induced damage, SCOF changes if the nature of the damage mechanism changes).

It was demonstrated that epoxy/ZrPM1000 coating had much lower SCOF than the other model systems before reaching plowing damage.

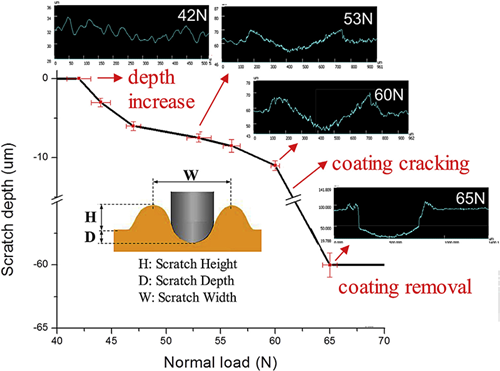

The cross-sectional profiles of scratchdamage on epoxy/ZrP-M1000 coating.

Results

The incorporation of ZrP in the epoxy coating leads to a significant improvement in scratch performance.

This structure enhances the bonding between hydroxyl-terminated functional groups on the ZrP surface and the epoxide functionality in the epoxy backbone, which increases connectivity and thus facilitates stress redistribution and load transfer. Also, VLSCM observation of epoxy/ZrP-M1000 coating demonstrated that scratch-induced microcracking damage propagates through the coating into the substrate without observing delamination.

This observation demonstrates the good adhesion between epoxy/ZrP-M1000 and neat epoxy substrate and suggests that delamination strength in this system is higher than the intrinsic cohesive strengths of both the coating and the substrate. This good adhesion facilitates the coating-to-substrate load transfer, and thus improves scratch resistance.

Developing new coating systems for high-performance applications

Follow WeChat