Sunshine Factory, Co., Ltd. > Applications > ZrP for CoatingZrP for Coating

Effects of zirconium phosphate on thermal degradation and flame retardancy of transparent intumescent fire protective coating

Introduction

Herein, a synergistic agent, OZrP, was introduced into UV- curable systems.

The FR consisted of phosphorus monomer (PDHA) and triglycidyl isocyanurate acrylate (TGICA).

The main attention of this paper was focused on the synergistic effect in flame retardant coatings.

The enhancement of thermal stability and the improvement of flame retardancy were observed.

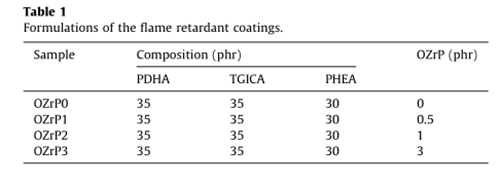

Preparation of the samples

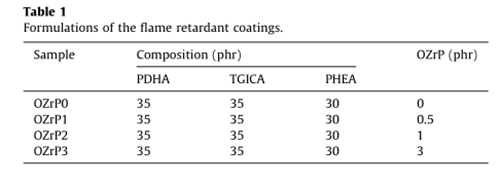

To prepare PDHA/TGICA/PHEA/OZrP nanocomposite, a certain amount of OZrP powder was dispersed in the solution containing PDHA, TGICA and PHEA (listed in Table 1) using ultrasonic treatment for 3 h, and then stirred for another 24 h at ambient temperature.

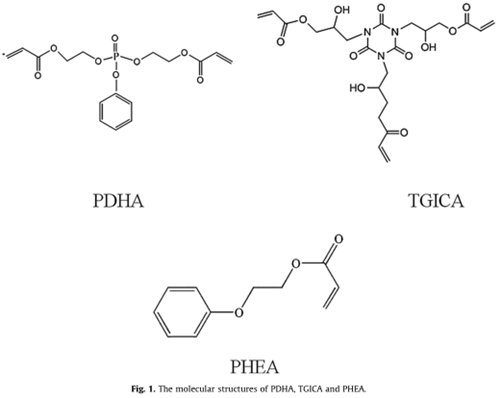

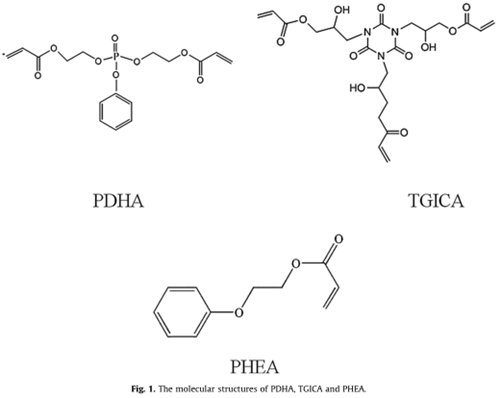

The molecular formulas of PDHA and TGICA were shown in Fig. 1.

Results and discussion

Microstructure of PDHA/TGICA/PHEA/OZrP nanocomposites

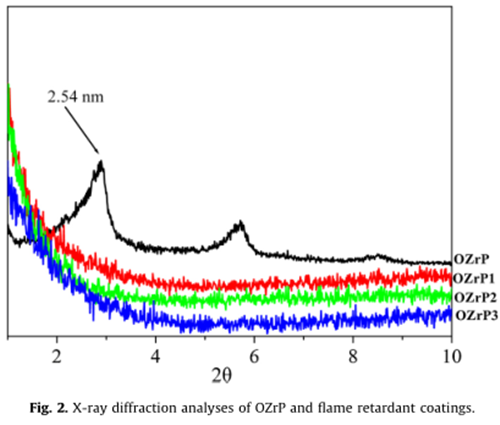

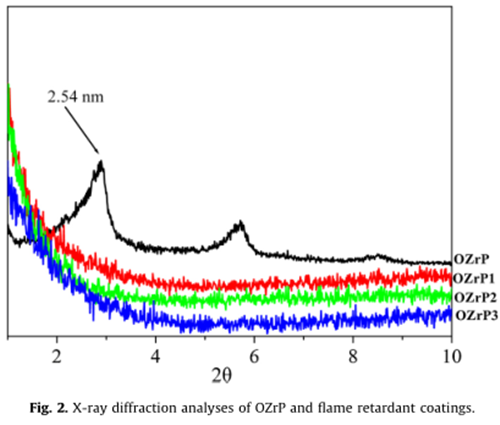

Fig. 2 shows the XRD patterns of OZrP, OZrP1, OZrP2 and OZrP3.

It can be seen that the characteristic diffraction peak of OZrP appears at 2θ= 2.9° corresponding to an interplanar spacing of 2.54 nm.

For the nanocomposites, no peak within the range of 2°–10° for OZrP1,OZrP2 and OZrP3 appears.

The results indicate that the OZrP nano-sheets could be exfoliated or randomly dispersed in the matrix resins.

The combustion of the UV-cured coatings

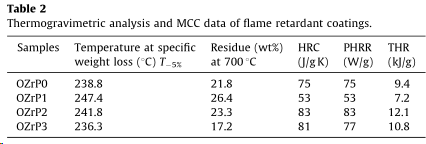

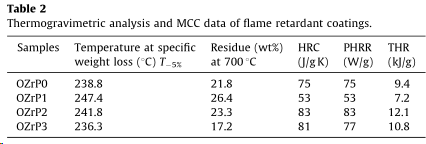

MCC was one of the most effective bench scale methods for investigating the combustion properties of polymer materials Fig. 4 and Table 2 outline the results obtained for different samples on the MCC instrument.

It can be observed that the peak heat release rate (PHRR) and total heat release (THR) of OZrP1 is decreased by 29.3% and 23.4%, respectively.

This phenomenon is probably attributed to that excess phosphate may restrain the expansion of IFR in the resins.

OZrP1 shows the lowest HRC and PHRR, resulting from the following reasons: OZrP could retard the degradation of polymer due to the dispersion of exfoliated or intercalated OZrP nano-sheets, promote resins forming more effective and protective char layer and reduce the release rate of inflammable gas.

Thermal behavior

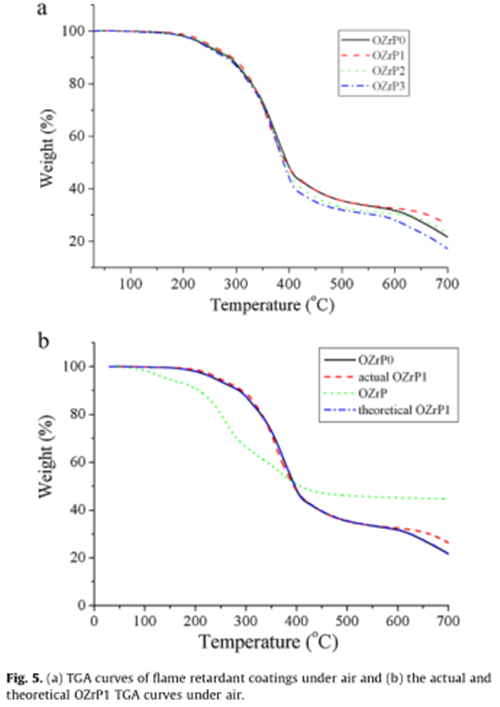

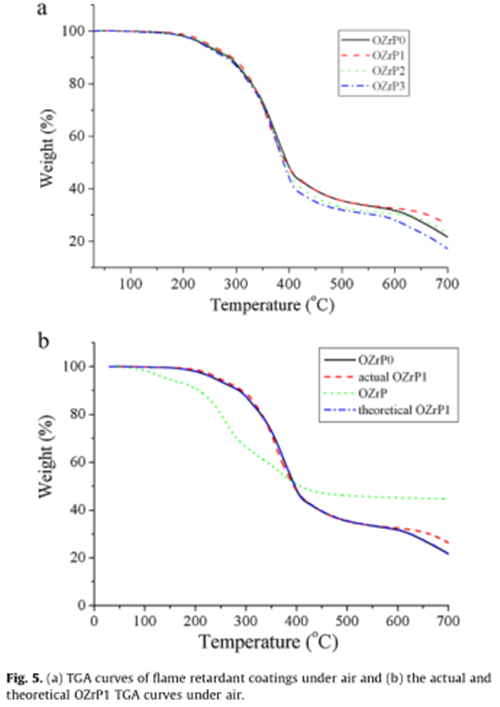

It is shown that the thermal degradation process of the flame retardant coatings modified with 0.5–3 wt% OZrP is similar to that of OZrP0 in the whole temperature range, as observed in Fig. 5.

The difference between the coatings modified with 0.5–3 wt% OZrP and the PDHA–TGICA–PHEA coating is the residue weight.

Especially,OZrP1 has the highest char residue (26.4%) among these samples.

This means that OZrP could promote the matrix resins to further form the carbonaceous materials.

Furthermore, the well dispersed OZrP platelets in the polymer matrix hinder the movement of polymer chains.

However, excess phosphate may restrain the expansion of IFR in the OZrP2 and OZrP3 coatings.

The result is in good agreement with the above-mentioned MCC study.

Characterization of the char layer

The high quality char acts as an insulating barrier during combustion, and this protective barrier can limit the volatiles diffusion to the flame zone.

The analysis of char materials can provide an insight into fire resistant performance.

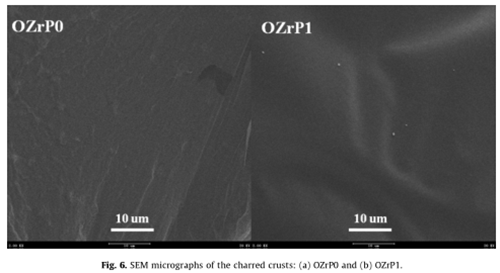

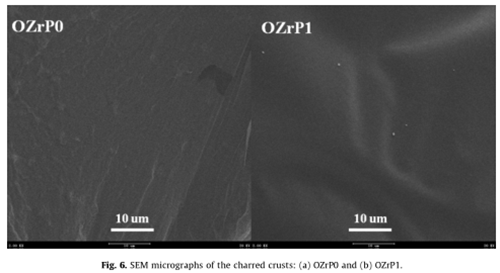

The morphologies of the char residues for the films after cone calorimeter testing are examined by SEM.

As shown in Fig. 6, the residual char of OZrP0 presents a discontinuous char layer on which are dispersed some folds and pits.

In contrast, the residual char of OZrP1 is flatter and more compact.

The compact char structure is very important to general fire resistant properties of the coatings,which can prevent the heat transfer between the flame zone

and the underlying substrate, and thus protect the substrate from heat and fire.

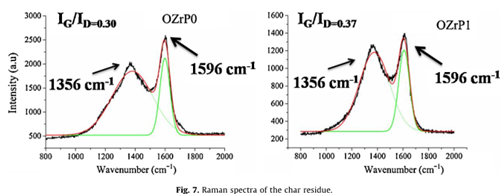

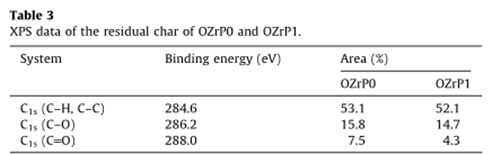

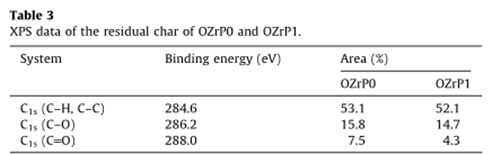

Structure analysis of the char residue

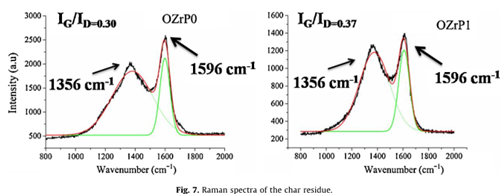

This reduction in Cox/Ca value indicates the presence of OZrP improves the thermal oxidative resistance of the protective char layer, which could effectively inhibit the heat and mass transmission, and thus retard the combustion.

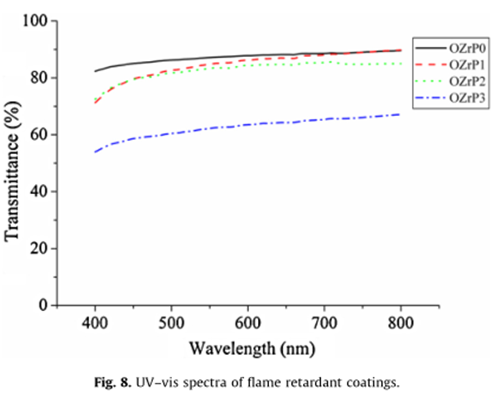

UV–vis analysis of flame retardant coatings

Conclusion

In this research, a synergistic agent (OZrP) was introduced into transparent intumescent fire protective coating.

The main attention of this paper was focused on the effect of OZrP on thermal degradation and flame retardancy of coating.

MCC results showed that the peak heat release rate and total heat of combustion of coatings with OZrP were significantly reduced.

And the char yield was evidently enhanced.

The highest improvement was achieved with 0.5 wt% OZrP.

XPS analysis indicated that the performance of anti-oxidation of the coating was improved with the addition of OZrP, and SEM images showed that OZrP could promote the char to form the flatter and more compact char.

(Above Contents from State Key Laboratory of Fire Science, University of Science and Technology of China supprot ,lists available at ScienceDirect)

Herein, a synergistic agent, OZrP, was introduced into UV- curable systems.

The FR consisted of phosphorus monomer (PDHA) and triglycidyl isocyanurate acrylate (TGICA).

The main attention of this paper was focused on the synergistic effect in flame retardant coatings.

The enhancement of thermal stability and the improvement of flame retardancy were observed.

Preparation of the samples

To prepare PDHA/TGICA/PHEA/OZrP nanocomposite, a certain amount of OZrP powder was dispersed in the solution containing PDHA, TGICA and PHEA (listed in Table 1) using ultrasonic treatment for 3 h, and then stirred for another 24 h at ambient temperature.

The molecular formulas of PDHA and TGICA were shown in Fig. 1.

Results and discussion

Microstructure of PDHA/TGICA/PHEA/OZrP nanocomposites

Fig. 2 shows the XRD patterns of OZrP, OZrP1, OZrP2 and OZrP3.

It can be seen that the characteristic diffraction peak of OZrP appears at 2θ= 2.9° corresponding to an interplanar spacing of 2.54 nm.

For the nanocomposites, no peak within the range of 2°–10° for OZrP1,OZrP2 and OZrP3 appears.

The results indicate that the OZrP nano-sheets could be exfoliated or randomly dispersed in the matrix resins.

The microstructure of nanocomposite was further confirmed by TEM observation.

As shown in Fig. 3, the TEM images of OZrP2 show that some OZrP could be exfoliated and some OZrP stacks still exist in the resin matrix.

As shown in Fig. 3, the TEM images of OZrP2 show that some OZrP could be exfoliated and some OZrP stacks still exist in the resin matrix.

The combustion of the UV-cured coatings

MCC was one of the most effective bench scale methods for investigating the combustion properties of polymer materials Fig. 4 and Table 2 outline the results obtained for different samples on the MCC instrument.

It can be observed that the peak heat release rate (PHRR) and total heat release (THR) of OZrP1 is decreased by 29.3% and 23.4%, respectively.

This phenomenon is probably attributed to that excess phosphate may restrain the expansion of IFR in the resins.

OZrP1 shows the lowest HRC and PHRR, resulting from the following reasons: OZrP could retard the degradation of polymer due to the dispersion of exfoliated or intercalated OZrP nano-sheets, promote resins forming more effective and protective char layer and reduce the release rate of inflammable gas.

Thermal behavior

Fig. 5(a)shows the TGA curves of flame retardant coatings in air atmosphere.

Obviously, OZrP0 shows more weight loss in the range of 300–400 ℃ from TGA curves. This is mainly due to poly(phosphoric acid)s, the degradation products of PDHA around 280 ℃ , which can catalyze the breakage of carbonyl groups to form more stable polynuclear aromatic structures .

As a result, the flame retardant coatings are more stable over 400℃ .

Therefore a plateau was seen between 400 ℃ and 600 ℃. This plateau might be assigned to a particular protective shield .

Finally, OZrP0 shows another degradation stage in the range of 600–700 ℃, which may be attributed to the decomposition of the unstable char.

During the oxidation process, the char yield decreases as the temperature increases.

The carbonaceous structure is no longer protective in this stage and "high temperature" residue was formed.

The residual weight of the sample is about 21.8% at 800 ℃.

Obviously, OZrP0 shows more weight loss in the range of 300–400 ℃ from TGA curves. This is mainly due to poly(phosphoric acid)s, the degradation products of PDHA around 280 ℃ , which can catalyze the breakage of carbonyl groups to form more stable polynuclear aromatic structures .

As a result, the flame retardant coatings are more stable over 400℃ .

Therefore a plateau was seen between 400 ℃ and 600 ℃. This plateau might be assigned to a particular protective shield .

Finally, OZrP0 shows another degradation stage in the range of 600–700 ℃, which may be attributed to the decomposition of the unstable char.

During the oxidation process, the char yield decreases as the temperature increases.

The carbonaceous structure is no longer protective in this stage and "high temperature" residue was formed.

The residual weight of the sample is about 21.8% at 800 ℃.

It is shown that the thermal degradation process of the flame retardant coatings modified with 0.5–3 wt% OZrP is similar to that of OZrP0 in the whole temperature range, as observed in Fig. 5.

The difference between the coatings modified with 0.5–3 wt% OZrP and the PDHA–TGICA–PHEA coating is the residue weight.

Especially,OZrP1 has the highest char residue (26.4%) among these samples.

This means that OZrP could promote the matrix resins to further form the carbonaceous materials.

Furthermore, the well dispersed OZrP platelets in the polymer matrix hinder the movement of polymer chains.

However, excess phosphate may restrain the expansion of IFR in the OZrP2 and OZrP3 coatings.

The result is in good agreement with the above-mentioned MCC study.

The high quality char acts as an insulating barrier during combustion, and this protective barrier can limit the volatiles diffusion to the flame zone.

The analysis of char materials can provide an insight into fire resistant performance.

The morphologies of the char residues for the films after cone calorimeter testing are examined by SEM.

As shown in Fig. 6, the residual char of OZrP0 presents a discontinuous char layer on which are dispersed some folds and pits.

In contrast, the residual char of OZrP1 is flatter and more compact.

The compact char structure is very important to general fire resistant properties of the coatings,which can prevent the heat transfer between the flame zone

and the underlying substrate, and thus protect the substrate from heat and fire.

Structure analysis of the char residue

This reduction in Cox/Ca value indicates the presence of OZrP improves the thermal oxidative resistance of the protective char layer, which could effectively inhibit the heat and mass transmission, and thus retard the combustion.

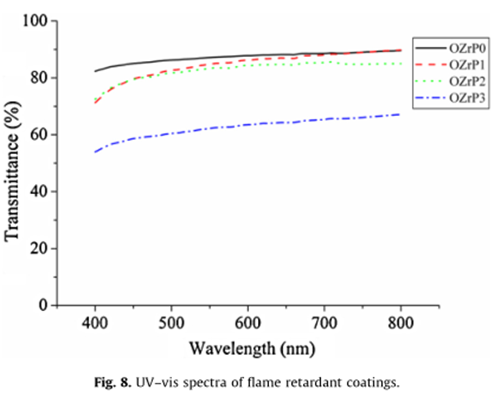

UV–vis analysis of flame retardant coatings

Fig. 8 shows the UV–vis spectra of the flame retardant coatings.

Each sample possesses the high transmittance over the visible light range of 400–800 nm.

This transmittance may be used as a criterion for the formation of a homogenous phase.

This phenomenon reveals the coatings have good optical transparency and compatibility, which is the most important characteristic for their application as protective coatings.

This transmittance may be used as a criterion for the formation of a homogenous phase.

This phenomenon reveals the coatings have good optical transparency and compatibility, which is the most important characteristic for their application as protective coatings.

In this research, a synergistic agent (OZrP) was introduced into transparent intumescent fire protective coating.

The main attention of this paper was focused on the effect of OZrP on thermal degradation and flame retardancy of coating.

MCC results showed that the peak heat release rate and total heat of combustion of coatings with OZrP were significantly reduced.

And the char yield was evidently enhanced.

The highest improvement was achieved with 0.5 wt% OZrP.

XPS analysis indicated that the performance of anti-oxidation of the coating was improved with the addition of OZrP, and SEM images showed that OZrP could promote the char to form the flatter and more compact char.

(Above Contents from State Key Laboratory of Fire Science, University of Science and Technology of China supprot ,lists available at ScienceDirect)

Follow WeChat