Sunshine Factory, Co., Ltd. > Applications > Lubricants, Lithium greaseLubricants, Lithium grease

Tuning Tribological Performance of Layered Zirconium Phosphate Nanoplatelets in Oil by Surface and Interlayer Modifications

Abstract

Information

In this study, we aim to differentiate the surface and interlayer modifications of ZrP nanoplatelets in order to sort out each effect on the tribological performance in mineral oil. We first attached silane coupling agents with different alkyl chain lengths onto the outer surface of ZrP nanoplatelets to increase their oil solubility and study the effect of surfactant molecule length on their lubricating efficiency in mineral oil. Such surface-modified ZrP nanoplatelets were then intercalated with alkyl amines to further investigate the interlayer modification effects.

Through these designed experiments, we have found that surface modification of ZrP nanoplatelets with a long alkyl chain and subsequent intercalation with short amine molecules are the most efficient in terms of reducing friction and wear in mineral oil. Our results demonstrate

the feasibility of tuning surface and interlayer functionalities of ZrP nanoplatelets for optimizing their tribological properties in oil mediums, which would be of great benefit in designing practical applications of lubricating oils containing ZrP nanoplatelets.

Methods

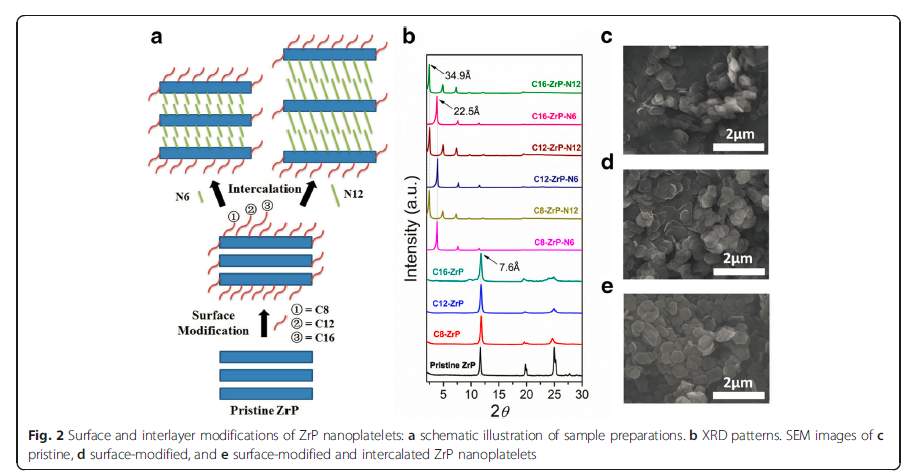

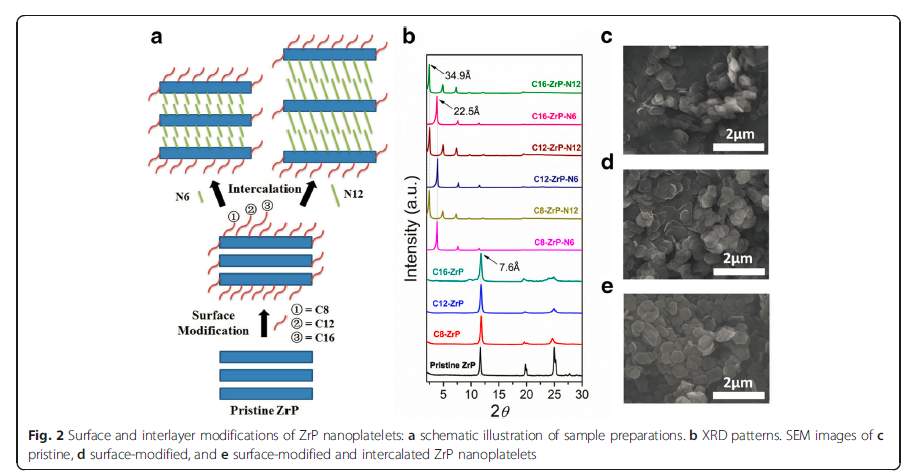

1. Surface Modification of Pristine ZrP Nanoplatelets

Ten grams of pristine ZrP and 20 g of three alkyl silanes(> 95%, Aladdin), including trimethoxyoctylsilane (C8),dodecyltrimethoxysilane (C12), and hexadecyltrimethoxysilane(C16), were first dissolved by toluene in a 500-mL three-necked flask, respectively. The mixtures were then placed into an oil bath at 100 °C with a constant stirring for 48 h. After the reaction, the solvents were removed by centrifugation and the solid samples were washed by centrifugation for three times using petroleum ether. The surface-modified ZrP nanoplatelets were dried at 70 °C in an oven for 24 h. Finally, the dried ZrP samples were ground with a mortar and pestle into fine powders before further uses. These three surface-modified ZrP nanoplatelets were identified as C8-ZrP, C12-ZrP, and C16-ZrP,respectively.

2. Interlay Modification of ZrP Nanoplatelets

Two grams of surface-modified ZrP nanoplatelets (C8-ZrP,C12-ZrP, and C16-ZrP) and primary alkyl amines including 5 g of hexylamine (N6) and 10 g of 1-dodecanamine (N12)were dissolved in 60 mL hexane using a 100-mL glass bottle,respectively. The mixtures were then treated by ultrasonication(40 kHz) for 3 h at room temperature. After ultrasonic treatment, the samples were washed by centrifugation for three times using petroleum ether. The intercalated ZrP nanoplatelets were dried at 70 °C in an oven for 24 h. These six intercalated ZrP samples with different surface modifications were identified as C8-ZrP-N6, C8-ZrPN12, C12-ZrP-N6, C12-ZrP-N12, C16-ZrP-N6, and C16-ZrP-N12, respectively.

Preparation of Nanolubricating Oils Containing ZrP Nanoplatelets

The concentration of ZrP nanoplatelets with various modifications in oils was determined to be 0.1 wt% for tribological studies. Master batch oils containing 1.0 wt% of different ZrP samples were first prepared by directly mixing each solid powder with mineral oils under mechanical stirring, followed by ultrasonication for about 20 min to obtain homogeneous oil mixtures. Each stock oil mixture was then diluted to 0.1 wt% using base mineral oil under ultrasonication.

Characterizations

Conclusions

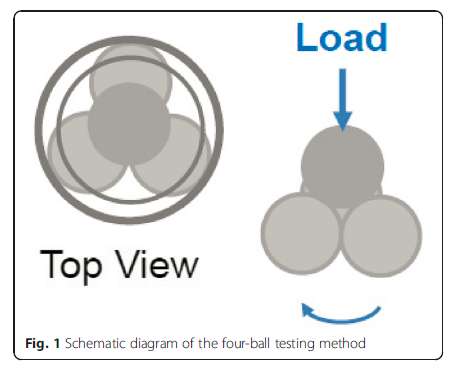

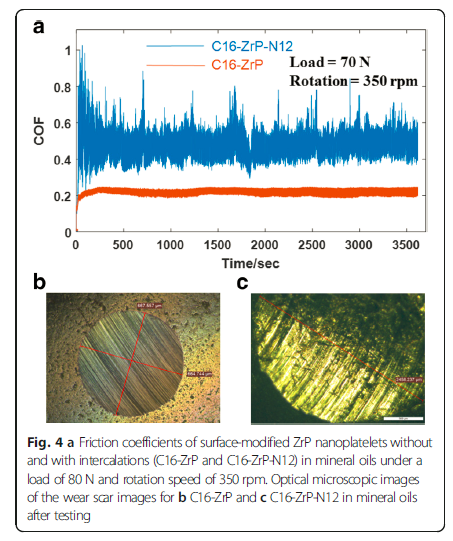

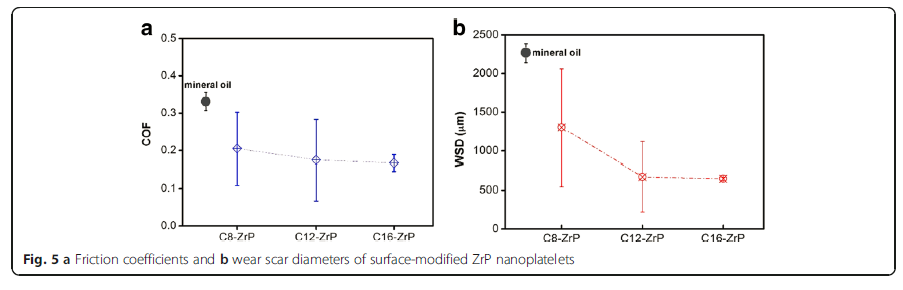

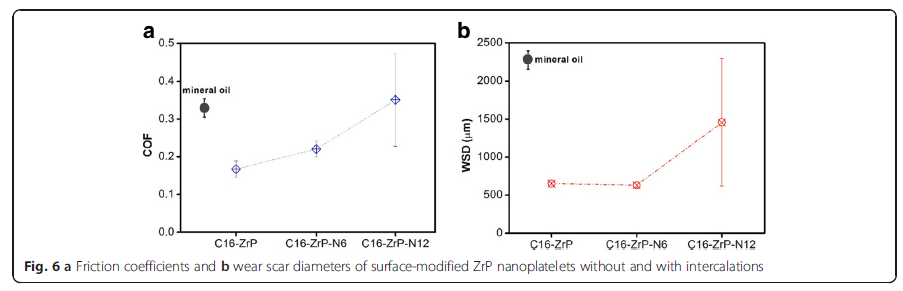

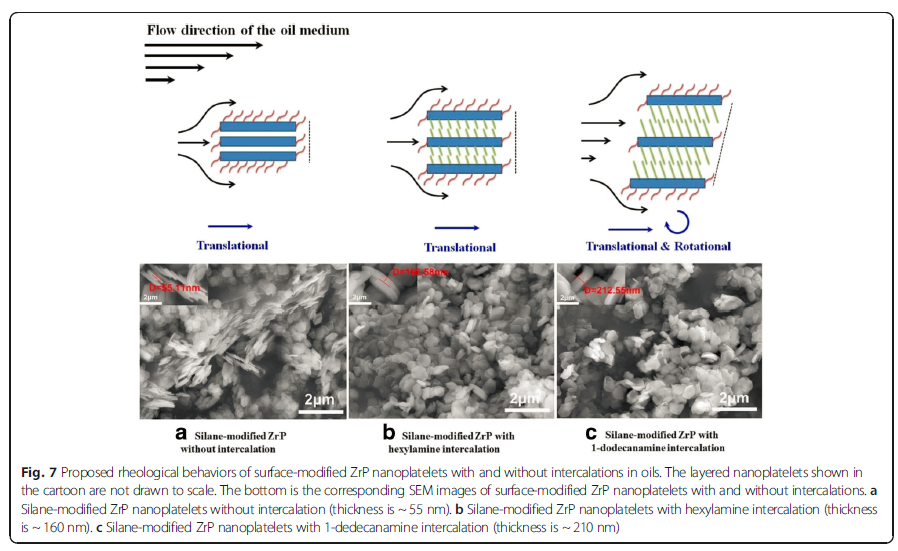

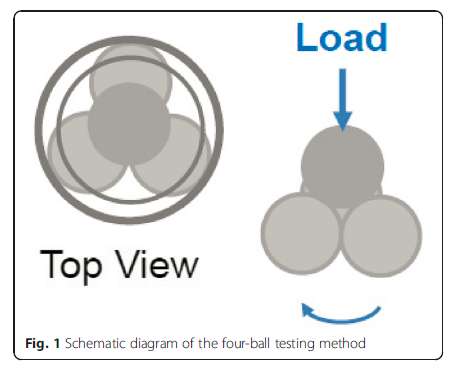

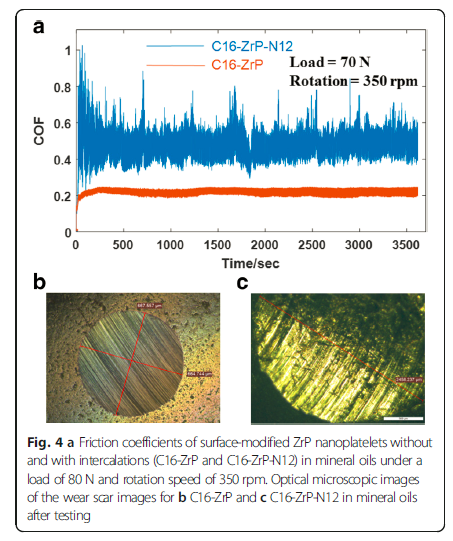

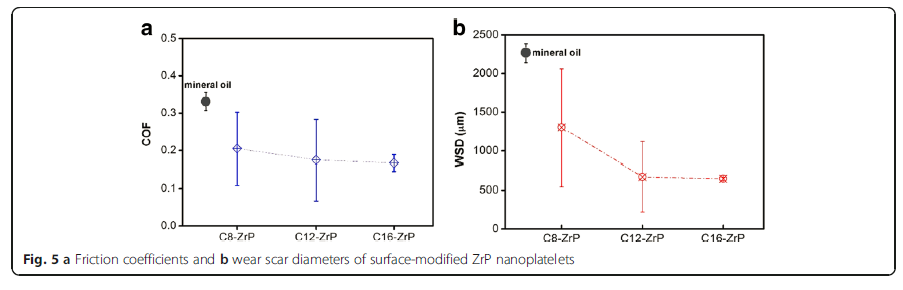

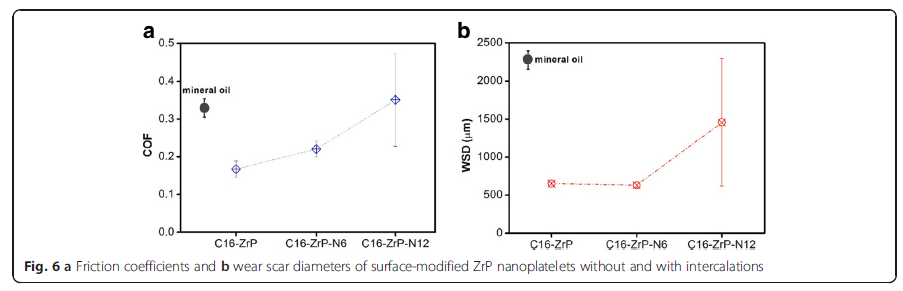

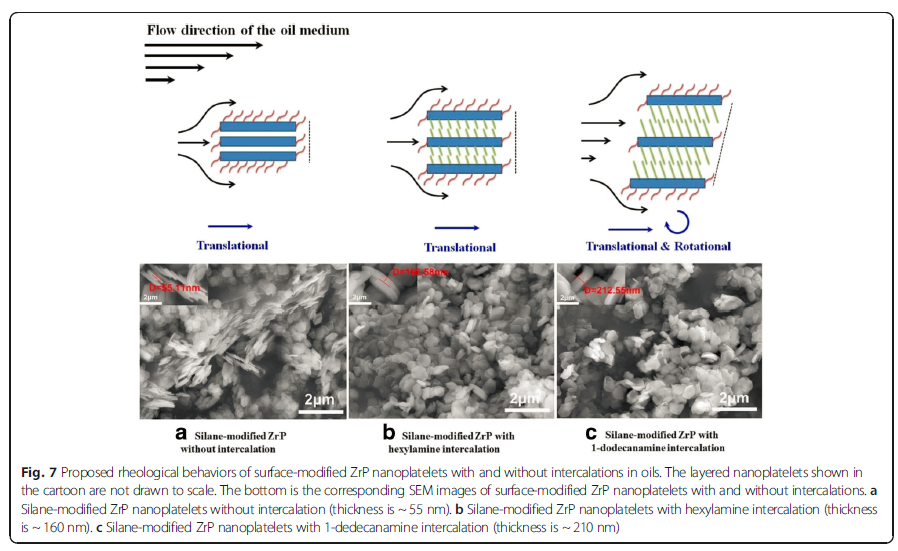

In summary, we have investigated the effects of surface and interlayer modifications on the tribological properties of layered ZrP nanoplatelets in mineral oil. Instead of directly using alkyl amines to intercalate and disperse ZrP nanoplatelets in oils, silane coupling agents with C8-, C12-, and C16-alkyl chains were first utilized to modify the outer surfaces of the pristine ZrP without any intercalations to study the surface modification effect. Such surface-modified ZrP nanoplatelets were further intercalated by hexylamine and 1-dodecanamine to investigate the interlayer modification effect. The standard four-ball tribological measurements on the friction coefficients and wear damages of nanolubricating oils containing various modified ZrP nanoplatelets illustrate that a longer alkyl chain on the outer surfaces will result in a better tribological performance and a further intercalation with 1-dodecanamine will cause a significant decrease in the tribological performance.

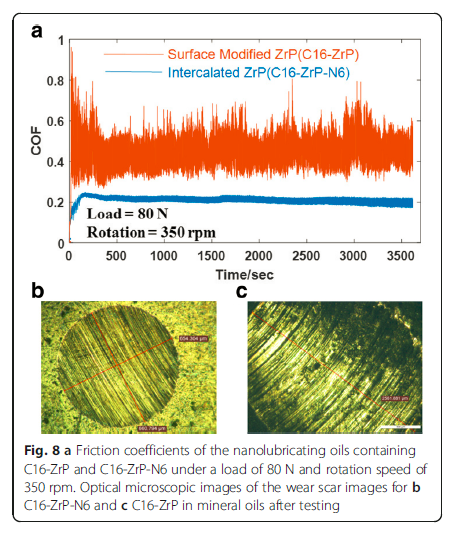

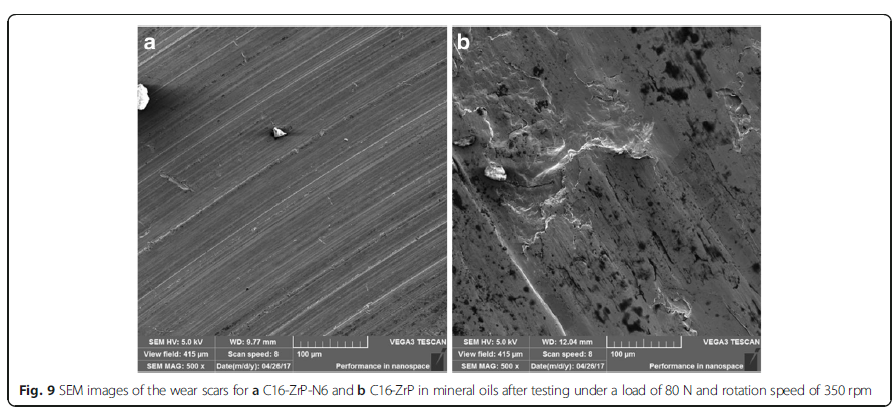

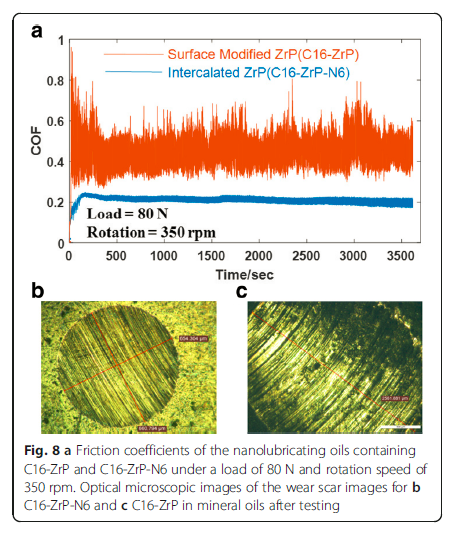

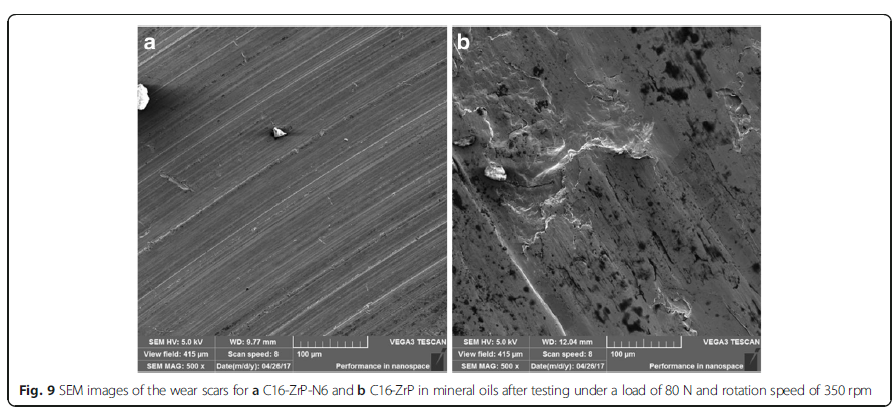

When the surface-modified ZrP nanoplatelets are intercalated with hexylamine, the tribological behavior of the nanolubricating oil is similar to the one without any intercalation under a load of 70 N. However, when the testing load is increased to 80 N, the surface-modified ZrP nanoplatelets with hexylamine intercalation show much better tribological properties than the ones without any intercalation in mineral oil. Our findings demonstrate the importance of tuning surface and interlayer modifications of 2D-layered nanolubricating additives for better tribological performance and are of great significance in designing high-performance nanolubricating oils for practical uses.

Two-dimensional (2D) inorganic layered nanoplatelets exhibit superior lubricating properties in both solid states and oil dispersions. In this paper, we have systematically investigated the effects of surface and interlayer modifications on the tribological performance of layered α-zirconium phosphate (ZrP) nanoplatelets in mineral oil. The pristine layered ZrP nanoplatelets were first reacted with silanes of different alkyl chains to achieve outer surface modifications, followed by intercalation with different alkyl amines to alter the interlayer spacing. Friction and anti-wear studies on ZrP nanoplatelets with various modifications in mineral oils suggest that a longer alkyl chain on the outer surfaces along with a small increase in interlayer spacing would lead to a better tribological behavior especially under a relatively heavy load condition. Our results illustrate the ability of tuning the tribological properties of 2D layered nanoplatelets in oils by varying their surface and interlayer functionalities and would be helpful for understanding the underlying tribological mechanisms of nanolubricating oils containing 2D layered nanoplatelets.

Information

In this study, we aim to differentiate the surface and interlayer modifications of ZrP nanoplatelets in order to sort out each effect on the tribological performance in mineral oil. We first attached silane coupling agents with different alkyl chain lengths onto the outer surface of ZrP nanoplatelets to increase their oil solubility and study the effect of surfactant molecule length on their lubricating efficiency in mineral oil. Such surface-modified ZrP nanoplatelets were then intercalated with alkyl amines to further investigate the interlayer modification effects.

Through these designed experiments, we have found that surface modification of ZrP nanoplatelets with a long alkyl chain and subsequent intercalation with short amine molecules are the most efficient in terms of reducing friction and wear in mineral oil. Our results demonstrate

the feasibility of tuning surface and interlayer functionalities of ZrP nanoplatelets for optimizing their tribological properties in oil mediums, which would be of great benefit in designing practical applications of lubricating oils containing ZrP nanoplatelets.

Methods

1. Surface Modification of Pristine ZrP Nanoplatelets

Ten grams of pristine ZrP and 20 g of three alkyl silanes(> 95%, Aladdin), including trimethoxyoctylsilane (C8),dodecyltrimethoxysilane (C12), and hexadecyltrimethoxysilane(C16), were first dissolved by toluene in a 500-mL three-necked flask, respectively. The mixtures were then placed into an oil bath at 100 °C with a constant stirring for 48 h. After the reaction, the solvents were removed by centrifugation and the solid samples were washed by centrifugation for three times using petroleum ether. The surface-modified ZrP nanoplatelets were dried at 70 °C in an oven for 24 h. Finally, the dried ZrP samples were ground with a mortar and pestle into fine powders before further uses. These three surface-modified ZrP nanoplatelets were identified as C8-ZrP, C12-ZrP, and C16-ZrP,respectively.

2. Interlay Modification of ZrP Nanoplatelets

Two grams of surface-modified ZrP nanoplatelets (C8-ZrP,C12-ZrP, and C16-ZrP) and primary alkyl amines including 5 g of hexylamine (N6) and 10 g of 1-dodecanamine (N12)were dissolved in 60 mL hexane using a 100-mL glass bottle,respectively. The mixtures were then treated by ultrasonication(40 kHz) for 3 h at room temperature. After ultrasonic treatment, the samples were washed by centrifugation for three times using petroleum ether. The intercalated ZrP nanoplatelets were dried at 70 °C in an oven for 24 h. These six intercalated ZrP samples with different surface modifications were identified as C8-ZrP-N6, C8-ZrPN12, C12-ZrP-N6, C12-ZrP-N12, C16-ZrP-N6, and C16-ZrP-N12, respectively.

Preparation of Nanolubricating Oils Containing ZrP Nanoplatelets

The concentration of ZrP nanoplatelets with various modifications in oils was determined to be 0.1 wt% for tribological studies. Master batch oils containing 1.0 wt% of different ZrP samples were first prepared by directly mixing each solid powder with mineral oils under mechanical stirring, followed by ultrasonication for about 20 min to obtain homogeneous oil mixtures. Each stock oil mixture was then diluted to 0.1 wt% using base mineral oil under ultrasonication.

Characterizations

Conclusions

In summary, we have investigated the effects of surface and interlayer modifications on the tribological properties of layered ZrP nanoplatelets in mineral oil. Instead of directly using alkyl amines to intercalate and disperse ZrP nanoplatelets in oils, silane coupling agents with C8-, C12-, and C16-alkyl chains were first utilized to modify the outer surfaces of the pristine ZrP without any intercalations to study the surface modification effect. Such surface-modified ZrP nanoplatelets were further intercalated by hexylamine and 1-dodecanamine to investigate the interlayer modification effect. The standard four-ball tribological measurements on the friction coefficients and wear damages of nanolubricating oils containing various modified ZrP nanoplatelets illustrate that a longer alkyl chain on the outer surfaces will result in a better tribological performance and a further intercalation with 1-dodecanamine will cause a significant decrease in the tribological performance.

When the surface-modified ZrP nanoplatelets are intercalated with hexylamine, the tribological behavior of the nanolubricating oil is similar to the one without any intercalation under a load of 70 N. However, when the testing load is increased to 80 N, the surface-modified ZrP nanoplatelets with hexylamine intercalation show much better tribological properties than the ones without any intercalation in mineral oil. Our findings demonstrate the importance of tuning surface and interlayer modifications of 2D-layered nanolubricating additives for better tribological performance and are of great significance in designing high-performance nanolubricating oils for practical uses.

Follow WeChat