Sunshine Factory, Co., Ltd. > Applications > ZrP for PolymerZrP for Polymer

Properties of poly(lactic acid) nanocomposites based on montmorillonite, sepiolite and zirconium phosphonate

Abstract

Poly(lactic acid) (PLA) based nanocomposites based on 5 wt.% of an organically modified montmorillonite(CLO), unmodified sepiolite (SEP) and organically modified zirconium phosphonate (ZrP) were obtained by melt blending.

Poly(lactic acid) (PLA) based nanocomposites based on 5 wt.% of an organically modified montmorillonite(CLO), unmodified sepiolite (SEP) and organically modified zirconium phosphonate (ZrP) were obtained by melt blending.

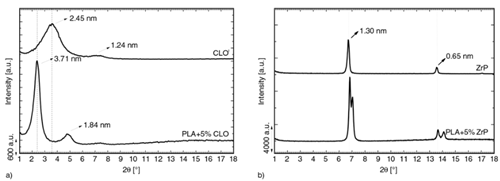

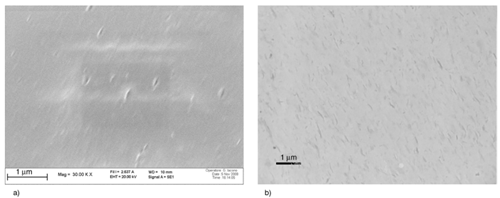

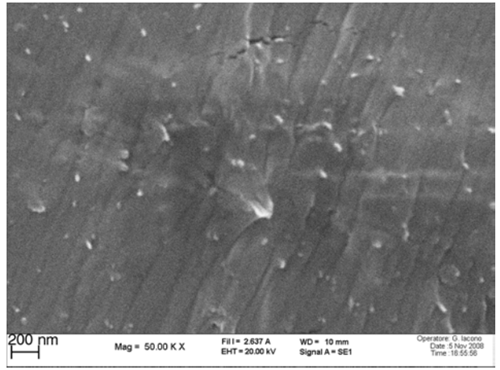

Wide angle X-ray scattering (WAXS) and scanning electron microscopy (SEM) analysis showed a different dispersion level depending on the type and functionalisation of nanoparticles.

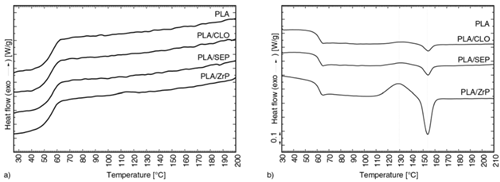

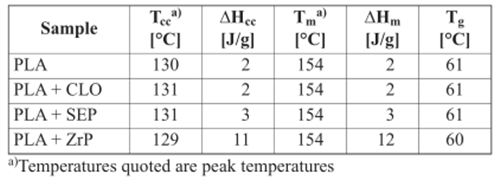

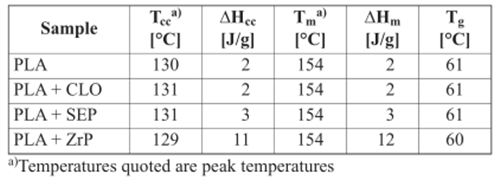

Differenctial scanning calorimetric (DSC) analysis showed that PLA was able to crystallize on heating, and that the addition of ZrP could promote extent of PLA crystallization,whereas the presence of CLO and SEP did not significantly affect the crystallization on heating and melting behaviour of PLA matrix.

Differenctial scanning calorimetric (DSC) analysis showed that PLA was able to crystallize on heating, and that the addition of ZrP could promote extent of PLA crystallization,whereas the presence of CLO and SEP did not significantly affect the crystallization on heating and melting behaviour of PLA matrix.

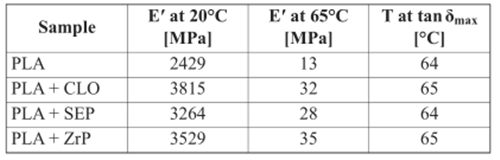

Dynamic Mechanical Thermoanalysis (DMTA) results showed that addition of all nanoparticles brought considerable improvements in E! of PLA, resulting in a remarkable increase of elastic properties for PLA nanocomposites.

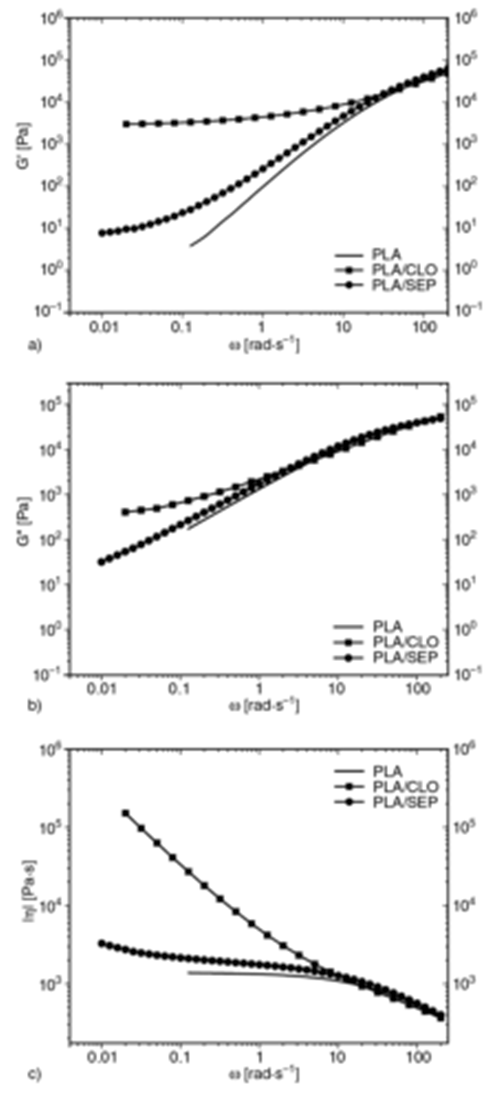

The melt viscosity and dynamic shear moduli (G',G") of PLA nanocomposites were also enhanced significantly by the presence of CLO and SEP, and attributed to the formation of a PLA/nanoparticle interconnected structure within the polymer matrix.

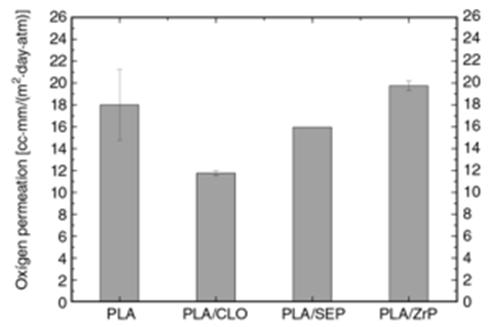

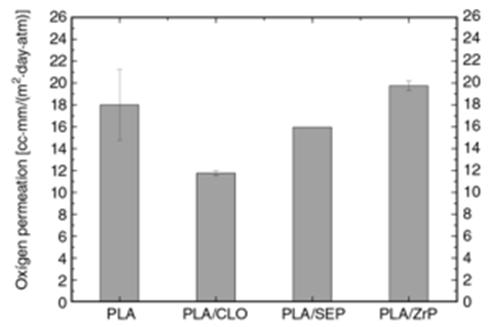

The oxygen permeability of PLA did not significantly vary upon addition of SEP and ZrP nanoparticles.

Only addition of CLO led to about 30% decrease compared to PLA permeability, due to the good clay dispersion and clay platelet-like morphology.

The characteristic high transparency of PLA in the visible region was kept upon addition of the nanoparticles.

Based on these achievements, a high potential of these PLA nanocomposites in sustainable packaging applications could be envisaged.

Only addition of CLO led to about 30% decrease compared to PLA permeability, due to the good clay dispersion and clay platelet-like morphology.

The characteristic high transparency of PLA in the visible region was kept upon addition of the nanoparticles.

Based on these achievements, a high potential of these PLA nanocomposites in sustainable packaging applications could be envisaged.

Results and discussion

WAXS patterns of PLA based composites with 5% (a) CLO and (b) ZrP

Scanning electron micrograph (a) and transmission electron micrograph (b) for PLA + 5% CLO

Scanning electron micrographs at 50 kX of magnification for PLA + 5% SEP. The cracks observed in the polymer matrix corresponds to matrix degradation under electron beam irradiation

Scanning electron micrographs for PLA + 5% ZrP

DSC thermograms of PLA and PLA/composites at (a) cooling and (b) second heating. Plots are vertically shifted for the sake of clarity

DSC data on PLA and PLA/nanocomposites obtained by second heating curves

Temperature dependence of storage modulus (E') for PLA and PLA/composites

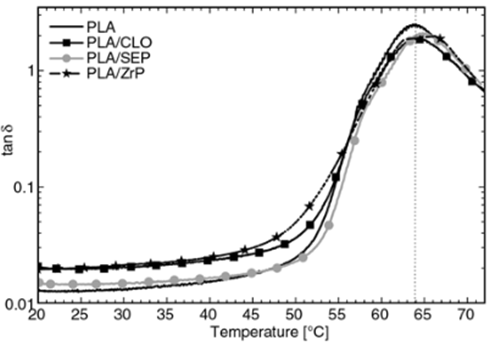

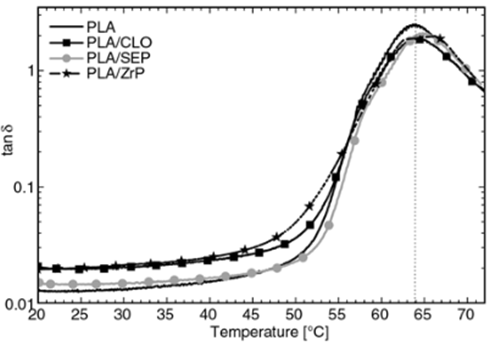

Temperature dependence of tan δ for PLA and PLA/composites

E’ and tan δ values of PLA and PLA/composites at 20 and 65°C. Estimated experimental error ±10%

Reduced frequency dependence of (a) storage modulus [G'(ω )], (b) loss modulus [G"(ω )], and(c) complex viscosity [|η*(ω)] at 190°C of neat PLA and PLA/composites

Oxygen gas permeability of PLA and PLA/composites, measured at 23°C and 0% relative humidity.

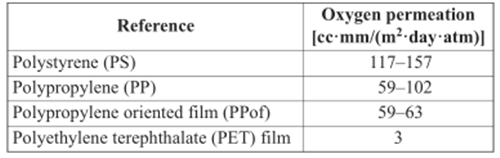

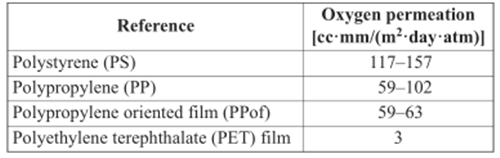

Oxygen permeation of PS, PP, PET films, values taken from Massey.

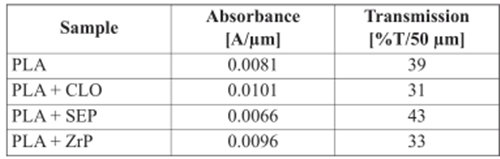

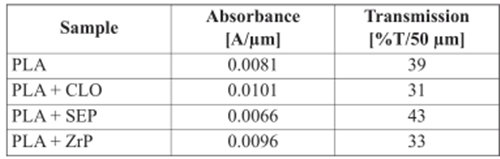

UV-visible transmission average results of PLA and PLA/nanocomposites from 380–780 nm wave- length. Experimental error 10%

Conclusions

Poly(lactic acid) (PLA) based nanocomposites prepared by adding 5 wt% filler content of organically modified montmorillonite (CLO) and unmodified sepiolite (SEP) were obtained by melt blending.

WAXS and SEM analysis showed a good dispersion of CLO and SEP into the polymer matrix.

PLA containing ZrP showed a limited dispersion on PLA matrix as compared to CLO, likely due to its significant lower interlayer thickness, leading to formation of a polymer microcomposite.

DSC analysis showed that neat PLA and composites presented no tendency to crystallise on cooling.

Nevertheless, it was observed that PLA was able to crystallize on heating, and that the addition of ZrP can promote the extent of crystallization of the PLA on

heating, which can be explained by the regular distribution of ZrP micronic particles able to act as efficient nucleating agents for PLA crystallization.

The dynamo-mechanical results showed improvements in E' with the addition of all particles, resulting in a remarkable increase of elastic properties for PLA composites, especially at temperatures close to the glass transition temperature.

These E' increases were associated to possible interactions between the particles and PLA molecules originated from hydrogen bonding between the carbonyl group of PLA and the hydroxyl groups belong to the structure of CLO, SEP and ZrP.

Interestingly, similar increases of E' were obtained upon the addition of ZrP into PLA as compared to CLO and SEP, despite its low dispersion level into the PLA matrix, possibly explained by the high crystallinity of ZrP particles as well as to the very regular distribution of ZrP micronic particles along all the polymer matrix.

These E' increases were associated to possible interactions between the particles and PLA molecules originated from hydrogen bonding between the carbonyl group of PLA and the hydroxyl groups belong to the structure of CLO, SEP and ZrP.

Interestingly, similar increases of E' were obtained upon the addition of ZrP into PLA as compared to CLO and SEP, despite its low dispersion level into the PLA matrix, possibly explained by the high crystallinity of ZrP particles as well as to the very regular distribution of ZrP micronic particles along all the polymer matrix.

The melt viscosity and dynamic shear moduli of nanocomposites were also enhanced significantly by the presence of CLO and SEP.

The dynamic shear storage modulus, G', and loss modulus, G" of these nanocomposites, exhibited less frequency dependence than pure PLA at a low frequency range.

These results could be attributed to important interactions between PLA and nanocomposites, especially CLO,forming an interconnected structure within the PLA

The dynamic shear storage modulus, G', and loss modulus, G" of these nanocomposites, exhibited less frequency dependence than pure PLA at a low frequency range.

These results could be attributed to important interactions between PLA and nanocomposites, especially CLO,forming an interconnected structure within the PLA

matrix.

Only addition of CLO leaded to an important decrease of the PLA oxygen permeability.

Optical transparency measurements showed the transparency of PLA in the visible region not to change significantly with the presence of particles, thus preserv-

The improvements of viscous and/or elastic properties for PLA composites as well as the similar transparency and improved gas barrier properties could provide to these composites an opportunity in the field of packaging.

Even more, it is reasonable to expect that by controlling the nanoparticle content and processing conditions, PLA based nanocomposites films with improved properties could be obtained for various purposes of industrial application.

<Department of Applied Science and Technology, Polytechnic of Turin>

The oxygen permeability of PLA did not significantly vary upon addition of SEP and ZrP particles.

Only addition of CLO leaded to an important decrease of the PLA oxygen permeability.

Optical transparency measurements showed the transparency of PLA in the visible region not to change significantly with the presence of particles, thus preserv-

ing the good optical properties typical of PLA.

The improvements of viscous and/or elastic properties for PLA composites as well as the similar transparency and improved gas barrier properties could provide to these composites an opportunity in the field of packaging.

Even more, it is reasonable to expect that by controlling the nanoparticle content and processing conditions, PLA based nanocomposites films with improved properties could be obtained for various purposes of industrial application.

<Department of Applied Science and Technology, Polytechnic of Turin>

Follow WeChat