Sunshine Factory, Co., Ltd. > Applications > ZrP for PolymerZrP for Polymer

Potential applications in low-permeability reservoirs

Introduction

But the development of low-permeability reservoirs was limited by their poor properties and poor injection production connectivity,which rapidly increases water injection pressure and dramatically decreases water intake capacity during the water flooding process.

In order to reduce water injection pressure and increase water injection volume, the flow resistance during water flooding should be reduced.

The contact angles of the core with water before and after the treatment by the nanomaterials could confirm the change of the wettability of the core surface.

In accordance with the mechanism of nanoslippage effect, it is considered that the nanomaterials have strong surface activity, and they perform competition adsorption with water molecules on the wall of themicropore.

Nanomaterials will replace the original hydration layer to form a molecular adsorption layer with superhydrophobic propertiesandnanoscale.

When the water flows through the adsorption layer, the nanoslippage effect generates, which helps to expand the effective pore size and reduce flow resistance.

Hydrophobic α-Zirconium Phosphate nanomaterial may exhibit a significant effect on decompression and augmented injection and can be used for low permeability reservoir water flooding development. In this paper, α-ZrP was modified by octadecyl isocyanate to obtain the hydrophobically modified product α-ZrP-I.

The performance of α-ZrP-I as a drag reducer was evaluated.

The experiment results show that α-ZrP-I has good performance in drag reduction, which has potential applications in low-permeability reservoirs.

Method

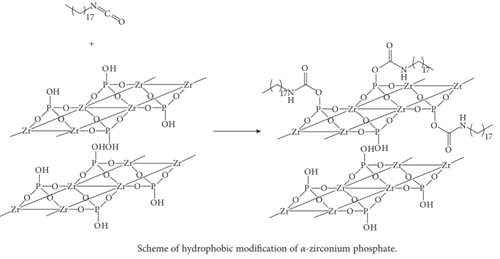

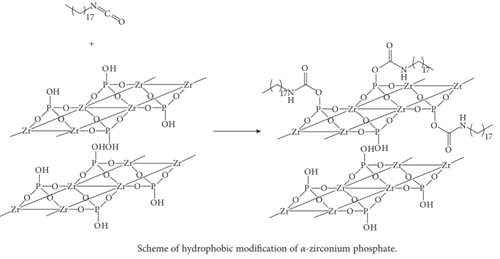

The reaction scheme is shown in Figure 1.

Evaluation of Core Flooding Experiment.

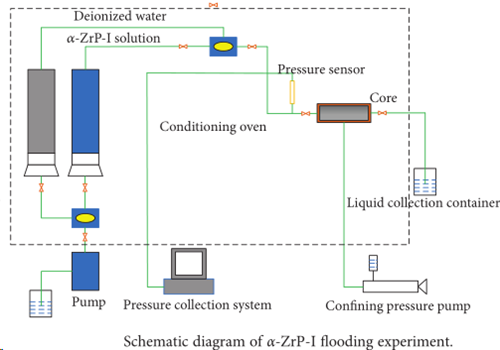

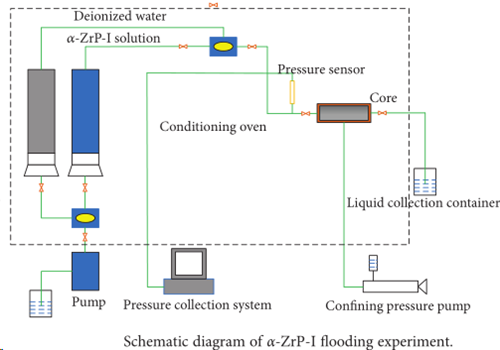

Schematic diagram of experiment is shown in Figure 2.

(1) Put the core into the core holder and inject deionized water in the core to determine the initial water-phase permeability of the core.

(2) Displace the cores with simulated oil.

(3) Displace the cores with deionized water again to set residual oil saturation and obtain the stable water flooding pressure P1 .

(4) Inject α-ZrP-I dispersion system, close the valve of the holder, and put it aside for 24 hours.

(5) Do subsequent water flooding injection to obtain the stable water flooding pressure P2

Results and Discussion

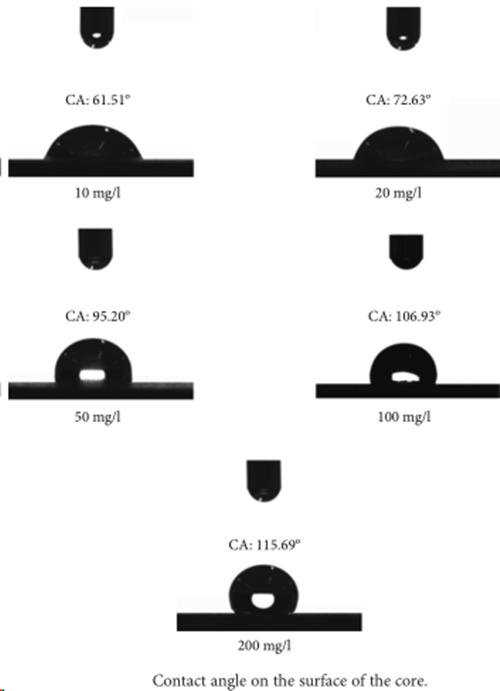

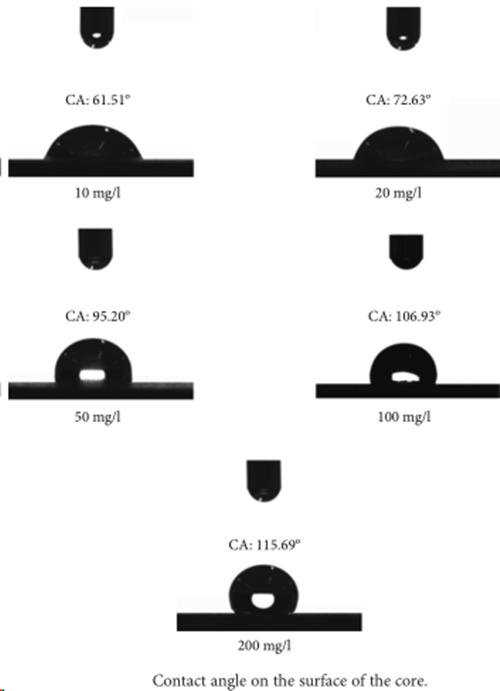

The surfaces of the hydrophilic core slices are polished with sandpaper and then soaked intetrahydrofuran dispersion systems of α-ZrP-I with the concentrations of 10mg/l, 20mg/l, 50mg/l, 100mg/l, and 200mg/l, respectively.

The dispersion is then heated and volatilized, depositing α-ZrP-I on the slice of the core.

The core slice which has not been processed by α-ZrP-I nanomaterial exhibited strong hydrophilicity.

The water droplet spreads rapidly as soon as it contacts the surface of the core due to the capillarity phenomenon.

The contact angle of the core with water can be considered as 0° .

When soaked in the α-ZrP-I dispersion systems at the concentration of 10mg/l and 20mg/l, respectively, the contact angles of the core slices with water are less than 90 ° .

When soaked in the dispersion systems at concentration higher than 50mg/l, the contact angles of the core slices with water are greater than 90°.

With the increase of concentration of the α-ZrP-I nanomaterial, the core surface is covered by more nanomaterial molecules,so the water droplet will contact with more hydrophobic groups and appear in the shape of a ball under the energy minimization and gravity, which accounts for the phenomenon that the wettability of the core surface changes from hydrophilic into hydrophobic.

Evaluation of Core Flooding Experiment

However, when the concentration of α-ZrP-I nano dispersion system exceeds a certain value, the nanoparticles will aggregate on the surface of the rock, which will not contribute to the decompression and augmented injection effect and will increase the injection pressure.

When the concentration of α-ZrP-I is more than 100mg/l, the depressurization effect disappears.

The results of the experiments in this paper show that 50mg/l is the best concentration for α-ZrP-I in decompression and augmented injection.

Therefore, the concentration of α-ZrP-I is crucial for decompression and augmented injection effect, which should be controlled within the appropriate range.

(Research Article :Hindawi Journal of Nanomaterials Volume 2018, Article ID 5873871, 9 pages)

With the development of oil and gas exploitation, many middle- and high-permeability reservoirs have been in medium or high water level development stage.

As a result,the low-permeability reservoirs will be the major resource.

As a result,the low-permeability reservoirs will be the major resource.

But the development of low-permeability reservoirs was limited by their poor properties and poor injection production connectivity,which rapidly increases water injection pressure and dramatically decreases water intake capacity during the water flooding process.

In order to reduce water injection pressure and increase water injection volume, the flow resistance during water flooding should be reduced.

The strong hydrophobic nanomaterials have the ability to make the surface wettability of the rock formation transform from hydrophilicity to hydrophobicity and then the subsequent injected water flows on the nanoadsorption layer.

The contact angles of the core with water before and after the treatment by the nanomaterials could confirm the change of the wettability of the core surface.

In accordance with the mechanism of nanoslippage effect, it is considered that the nanomaterials have strong surface activity, and they perform competition adsorption with water molecules on the wall of themicropore.

Nanomaterials will replace the original hydration layer to form a molecular adsorption layer with superhydrophobic propertiesandnanoscale.

When the water flows through the adsorption layer, the nanoslippage effect generates, which helps to expand the effective pore size and reduce flow resistance.

Hydrophobic α-Zirconium Phosphate nanomaterial may exhibit a significant effect on decompression and augmented injection and can be used for low permeability reservoir water flooding development. In this paper, α-ZrP was modified by octadecyl isocyanate to obtain the hydrophobically modified product α-ZrP-I.

The performance of α-ZrP-I as a drag reducer was evaluated.

The experiment results show that α-ZrP-I has good performance in drag reduction, which has potential applications in low-permeability reservoirs.

Method

1.416g α-ZrP was dispersed into 50ml o-xylene in a three-necked flask and ultrasonically dispersed for 2 hours (ultrasonic power was set at 100W).

0.150g octadecyl isocyanate was added into the α-ZrP dispersed system (the molar ratio of ZrP to ODI is 10:1.) and reacted for 12 hours under the condition of nitrogen gas.

Then, the mixture was centrifuged and the product was washed with methanol several times to remove impurities.

The product was dried in an oven at 60℃ to obtain the hydrophobically modified α-zirconium phosphate (α-ZrP-I) solid powder.

0.150g octadecyl isocyanate was added into the α-ZrP dispersed system (the molar ratio of ZrP to ODI is 10:1.) and reacted for 12 hours under the condition of nitrogen gas.

Then, the mixture was centrifuged and the product was washed with methanol several times to remove impurities.

The product was dried in an oven at 60℃ to obtain the hydrophobically modified α-zirconium phosphate (α-ZrP-I) solid powder.

The reaction scheme is shown in Figure 1.

Evaluation of Core Flooding Experiment.

Schematic diagram of experiment is shown in Figure 2.

The pressure during the injection process was recorded.

The injection rate was 0.5ml/min.

The detailed process is as follows:

The injection rate was 0.5ml/min.

The detailed process is as follows:

(1) Put the core into the core holder and inject deionized water in the core to determine the initial water-phase permeability of the core.

(2) Displace the cores with simulated oil.

(3) Displace the cores with deionized water again to set residual oil saturation and obtain the stable water flooding pressure P1 .

(4) Inject α-ZrP-I dispersion system, close the valve of the holder, and put it aside for 24 hours.

(5) Do subsequent water flooding injection to obtain the stable water flooding pressure P2

Results and Discussion

Here,octadecyl isocyanate was utilized to modify the surface of α-zirconium phosphate to prepare hydrophobically modified α-zirconium phosphate.

The octadecyl isocyanate was grafted onto the surface and the edge of the α-zirconium phosphate sheet by chemical reaction with the -OH group on the surface.

The octadecyl isocyanate was grafted onto the surface and the edge of the α-zirconium phosphate sheet by chemical reaction with the -OH group on the surface.

Evaluation of Wettability of Nanomaterial. The wettability of the nanometer material of α-ZrP-I is evaluated, and the results are shown in Figure below.

The surfaces of the hydrophilic core slices are polished with sandpaper and then soaked intetrahydrofuran dispersion systems of α-ZrP-I with the concentrations of 10mg/l, 20mg/l, 50mg/l, 100mg/l, and 200mg/l, respectively.

The dispersion is then heated and volatilized, depositing α-ZrP-I on the slice of the core.

The core slice which has not been processed by α-ZrP-I nanomaterial exhibited strong hydrophilicity.

The water droplet spreads rapidly as soon as it contacts the surface of the core due to the capillarity phenomenon.

The contact angle of the core with water can be considered as 0° .

When soaked in the α-ZrP-I dispersion systems at the concentration of 10mg/l and 20mg/l, respectively, the contact angles of the core slices with water are less than 90 ° .

When soaked in the dispersion systems at concentration higher than 50mg/l, the contact angles of the core slices with water are greater than 90°.

With the increase of concentration of the α-ZrP-I nanomaterial, the core surface is covered by more nanomaterial molecules,so the water droplet will contact with more hydrophobic groups and appear in the shape of a ball under the energy minimization and gravity, which accounts for the phenomenon that the wettability of the core surface changes from hydrophilic into hydrophobic.

The ability of decompression and augmented injection of nanoparticle dispersion system with different concentrations are evaluated by the self-made low

permeability core.

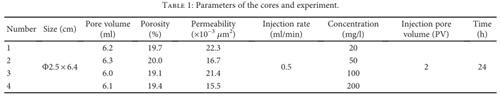

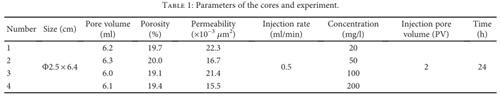

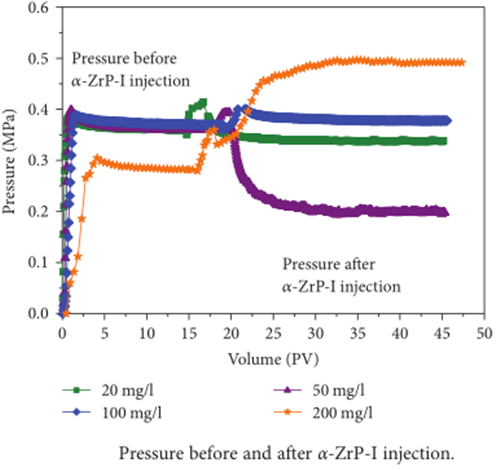

The experimental parameters are shown in Table 1.

The experiment is carried out at 30°C.

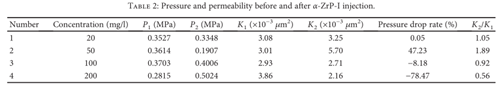

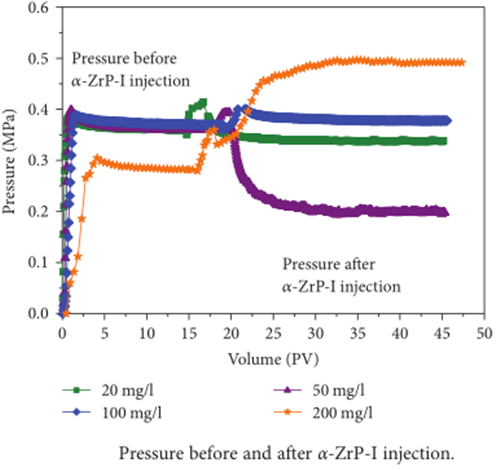

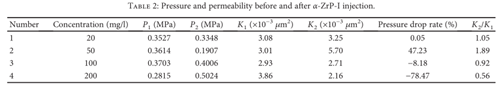

The pressure P1 and P2 before and after theinjection of α-ZrP-I nanometer material dispersion system are recorded, and the water-phase permeability K1 and K2 arecalculated according to the Darcy formula, which are shown in Table 2 and Figure below.

permeability core.

The experimental parameters are shown in Table 1.

The experiment is carried out at 30°C.

The pressure P1 and P2 before and after theinjection of α-ZrP-I nanometer material dispersion system are recorded, and the water-phase permeability K1 and K2 arecalculated according to the Darcy formula, which are shown in Table 2 and Figure below.

From Figure , it can be seen that the injection pressure after α-ZrP-I injection decreases at first and then increases with the increase of the concentration of α-ZrP-I.

When the injected concentration of α-ZrP-I is low, the surface of the rock could not be able to form an effective adsorption layer.

When the injected concentration of α-ZrP-I is low, the surface of the rock could not be able to form an effective adsorption layer.

Therefore, nanoslip impact is not obvious and the injection pressure has a little change.

As the concentration of α-ZrP-I increases to 50mg/l, the pressure drop rate is up to 47.23% and water permeability increased to 1.89 times.

The flow resistance is lowered through the slippage effect, which will play an important role in reducing the injection pressure.

As the concentration of α-ZrP-I increases to 50mg/l, the pressure drop rate is up to 47.23% and water permeability increased to 1.89 times.

The flow resistance is lowered through the slippage effect, which will play an important role in reducing the injection pressure.

However, when the concentration of α-ZrP-I nano dispersion system exceeds a certain value, the nanoparticles will aggregate on the surface of the rock, which will not contribute to the decompression and augmented injection effect and will increase the injection pressure.

When the concentration of α-ZrP-I is more than 100mg/l, the depressurization effect disappears.

The results of the experiments in this paper show that 50mg/l is the best concentration for α-ZrP-I in decompression and augmented injection.

Therefore, the concentration of α-ZrP-I is crucial for decompression and augmented injection effect, which should be controlled within the appropriate range.

(Research Article :Hindawi Journal of Nanomaterials Volume 2018, Article ID 5873871, 9 pages)

Follow WeChat