Sunshine Factory, Co., Ltd. > Applications > ZrP for PolymerZrP for Polymer

How Powerful Will Natural Fiber Composites Become?

In recent years, natural fiber reinforced composites have drawn continuous attention from both academics and industries, because of their ability of raw materials renewability and end-of-life biodegradability.Natural cellulose fabrics, such as ramie fabric, are usually used to combine with polymer resin to produce the natural fiber composites. However, the intrinsic inflammability of nature fibers and fabrics can be an issue for some applications, posing fire hazard and risk.industries and academics are working on the development of simple and efficient flame retardant systems for these natural materials.

In this study, LbL assembly method is used to deposit multilayer nanocoatings on ramie fabrics to achieve effective flame retardancy.

ABSTRACTIn this study, LbL assembly method is used to deposit multilayer nanocoatings on ramie fabrics to achieve effective flame retardancy.

Complex multilayer coatings composed of α-zirconium phosphate (ZrP), polyethylenimine (PEI), and ammonium polyphos-phate (APP) were constructed via layer-by-layer assembly method for flame retardant ramie fabric.

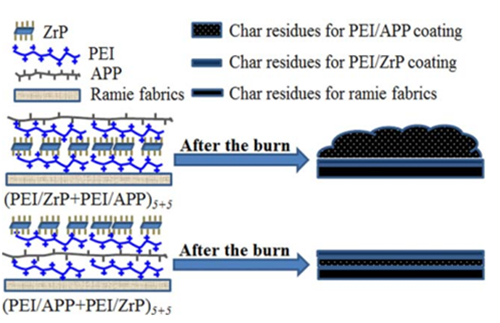

Bicomponent PEI/ZrP layers served as insulating barrier coating, and bicomponent PEI/APP layers served as intumescent coating.

The flame retardancy of the coated ramie fabric was strongly dependent on the nature of the coatings and the layer-by-layer assembly patterns.

The coated ramie fabric with inside PEI/ZrP layers and outside PEI/APP layers possessed the most uniform and consistent coating surface morphology, as well as the highest content of N and P elements, resulting in an excellent improvement in flame retardancy of ramie fabrics.

When this kind of coated ramie fabric was heated, the inner PEI/ZrP layer effectively prevent oxygen and heat from penetrating into the substrate, and the outer PEI/APPlayer exposed to air with good expansion during combustion.

The synergistic effect was formed during the combustion process and could impart ramie fabrics with high flame retardancy.

EXPERIMENTAL

1.Schematic illustration of the LbL assembly process for deposition multilayer coatings of ZrP, PEI, and APP.

2.The Formulations of the Ramie Fabrics

a, The value denoted the concentration used in the treatment process of ramie fabrics.

b ,The coating content was calculated by weighing :Coating content=[(weight of treated ramie fabric ramie – weight of pristine fabric ramie)/weight of pristine fabric ramie]×100%.

RESULTS AND DISCUSSION

1.TGA Results of the Pristine and Treated Ramie Fabrics under Nitrogen Conditions

TGA Results of the Pristine and Treated Ramie Fabrics under Air Atmosphere

Representative heat release rate curves for the pristine and treated ramie fabrics

Schematic illustration of flame retardancy mechanism for deposition multilayer coatings of ZrP, PEI, and APP.

Flammability and Combustion Properties Microscale Combustion Calorimetry Results for the Pristine and Treated Ramie Fabrics

The Comparison of Microscale Combustion Calorimetry Results Between (PEI/ZrP1PEI/APP) 5 +5 Coating Ramie Fabrics and Other Coating Ramie Fabrics

Top view SEM images (the first row, ×50; the second row, ×400) of the char residues after vertical flame test for the pristine (a,f) and treated ramie fabrics [(PEI/ZrP) 10 (b,g), (PEI/APP) 10 (c,h), (PEI/APP+PEI/ZrP) 5+5 (d,i), and (PEI/ZrP+PEI/APP) 5+5 (e,j)]

Analysis of the Collected Char Residues EDX spectra of the char residues after vertical flame test for the treated ramie fabrics (a) (PEI/ZrP)10 , (b) (PEI/APP)10 , (c) (PEI/APP+PEI/ZrP)5+5 , and (d) (PEI/ZrP+PEI/APP) 5+5

CONCLUSIONS

In this work, bicomponent insulating and intumescent coatings,and complex FR coatings have been deposited on the ramie fabric surface using LbL assembly technique.

The results from TG,MCC, and VFT indicated that the flame retardancy of the ramie fabrics could be significantly improved by LbL coatings and the performance of the coating was strongly dependent on the nature of the coating and the coating assembly.

The maximum reductions for HRC (–53%), PHRR (–53%), THR (–56%), and high char yield at 600℃ (27%) were achieved in the (PEI/ZrP+PEI/APP) 5+5 sample, suggesting that the PEI/ZrP(inside)-PEI/APP(outside) assembly pattern could endow ramie fabrics with good flame retardancy.

The sample formed dense and thick residue char preserving the original texture of the ramie fabrics and with intumescent-like bubbles on the ablation surface, and its char residue had the highest P/O and P/C ratios.

The superb flame retardancy could be attributed to the synergistic effect between the inner insulating PEI/ZrP layers’ shelter action and the outer intumescent PEI/APP layers’ good expansion.

(This R&D from J. APPL. POLYM. SCI. 2017, DOI: 10.1002/APP.45556 )

Follow WeChat